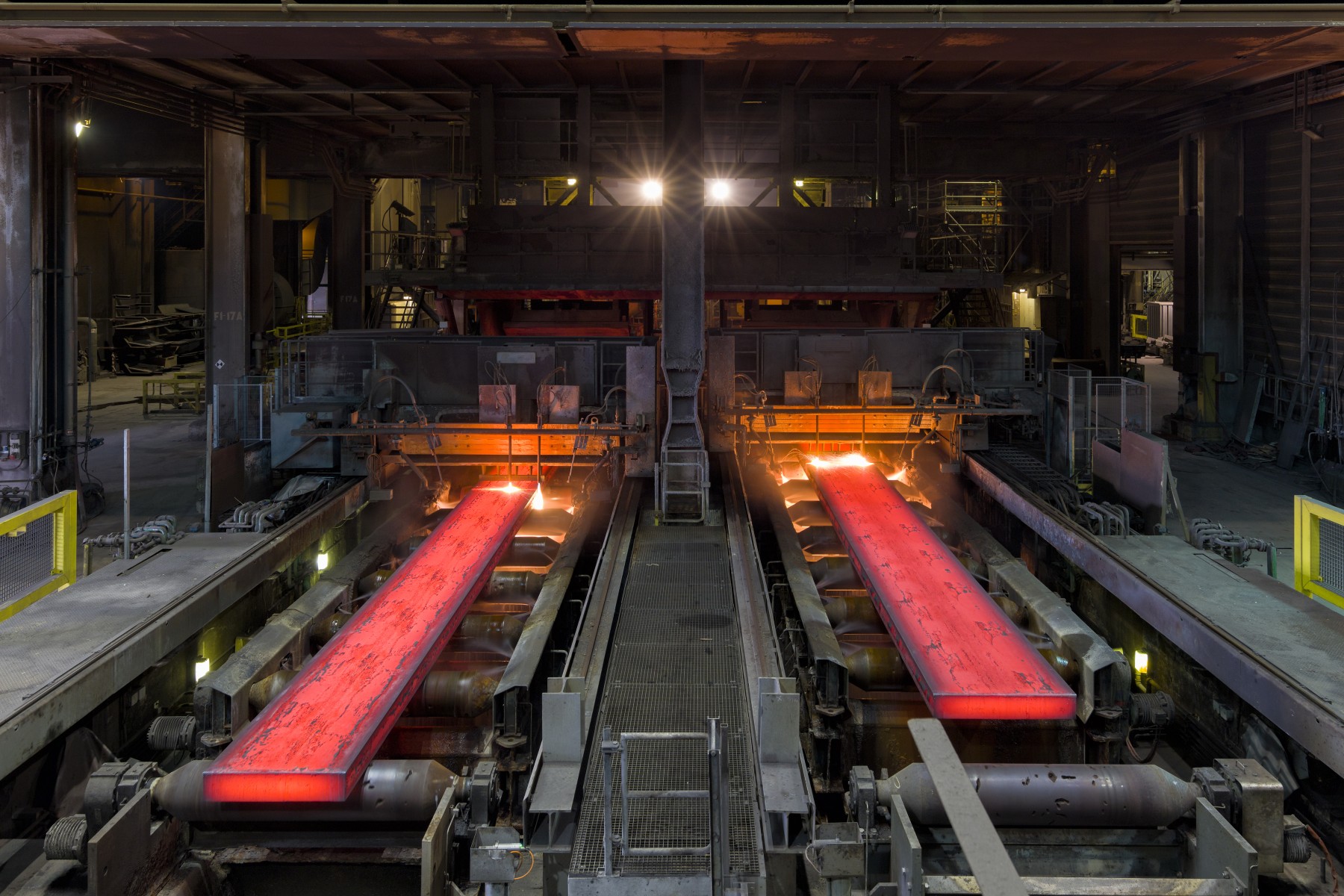

Tata Steel faces significant challenges due to unplanned downtimes across its manufacturing processes. The cost of halting production can approach €100,000 per hour, making the need for a more proactive approach to maintenance essential. Historically, reactive maintenance strategies led to two extremes: excessively conservative maintenance routines or unexpected machine breakdowns with extended downtime. The objective was clear: reduce unplanned downtime, mitigate repair costs, and optimize the use of resources within the production lines.

Xomnia helped develop data solutions to tackle these challenges at Tata Steel.

Utilizing the Databricks environment, they ensured efficient data processing, scheduled jobs for batch-wise data flows, and monitoring for a reliable deployment setup. The jobs send API messages to the AMDC platform, a custom tool which enables dashboard displays and real-time alerts for informed decision-making.

The first project focused on monitoring roller tables, which consisted of a thousand motors tasked with transporting heavy steel plates. With limited sensory data available, the team utilized indicators such as power consumption and speed to assess motor performance. By analyzing variations in expected vs. actual power levels, the Tata Steel team devised business logic to predict potential motor failures. Key features were engineered to identify abnormal behavior, supported by data aggregated at one-hour intervals. Xomnia’s key contribution was transforming these existing models into a scalable solution: the models are now applied to nine other roller tables, are fully tested, and are significantly more maintainable.

The solution allows real-time alerts to be generated when specific thresholds were breached, thus informing maintenance teams of deteriorating motors ahead of a breakdown. This proactive maintenance approach was enhanced through collaboration with on-site operators, ensuring relevant contextual knowledge was integrated into the predictive models. Now, with a proven use case and a scalable codebase, the next challenge is to expand the predictive maintenance to include other parts of Tata Steel.

In addition to the roller table monitoring project, the Scalex initiative was launched to create a scalable library of PySpark operations, enabling quick deployment for various use cases within Tata Steel. This framework allows operators to input simple configuration files (YAML) that define the necessary operations on any sensor data. For instance, temperature and humidity readings could trigger alerts based on the potential for rust formation on steel.

The Scalex project offers tools for efficiently observing and alerting on any type of industrial data collected on the shop floor. In collaboration with various data teams, AMDC has standardized dataflows from IBA—an industrial tool for collecting and storing sensor data—to the cloud, which is the starting point for Scalex. This development allows any shop-floor data user to request a Scalex solution suited to their specific needs, with the capability to roll out solutions quickly once alerting requirements are defined. Defining these requirements remains a challenge, since this requires utilizing stakeholder expertise in steel making during data exploration.

Both projects have shown promising results, demonstrated through a tangible reduction in costs associated with unplanned downtimes. Early estimates indicate that the AMDC initiatives could prevent damages worth approximately €2 million per year.

Tracking the effectiveness of alerts, the team at Xomnia collects feedback from operators on the alerts received and actions taken. While the reporting method is still evolving, initial feedback has provided useful insights into expected savings resulting from identified issues.

The dual approach not only aimed to save finances but also worked to establish a culture of proactive maintenance at Tata Steel. The collaborative efforts paved the way for a collective understanding of the importance of data-driven decision-making among operational managers and maintenance staff.

The partnership between Xomnia and Tata Steel illustrates a successful deployment of predictive maintenance solutions tailored to industry-specific challenges. Xomnia engineers have helped Tata Steel transition from custom solutions to robust, scalable systems, significantly increasing the speed of adding new use cases, making maintenance more feasible, and enhancing product reliability. By leveraging both monitoring technology and a flexible operational framework, Tata Steel has begun its journey toward minimizing unplanned downtimes and maximizing operational efficiency. As data continues to accumulate, further improvements and refinements in predictive maintenance strategies can be expected, underscoring the potential for technology to reimagine traditional industrial processes.